PRODUCTS

TECHNICAL INFORMATION

Specification

This specification defines material management, installing method, safety management, and receiving inspection etc.

when the PLAGLAS (polycarbonate single-layer sheet) made from Taekwang New Tec Co., Ltd. (“Company” hereinafter) is used as a construction material.

The construction must be done according to the design documents or specifications, in principle.

The matters that are not specified here should be done after discussing with an on-site supervisor and/or between “A” and “B”, and general matters are

to be constructed according to methods of a specialized construction company.

The criteria below are deemed to include portions of this specifications in the scope specified in this specification.

General terms

-

-

Product treatment

To prevent yellowing from the UV rays of the polycarbonate sheet and to prevent aesthetic damage from contaminations

such as dust and pollution, UV stabilizer should be applied (UV ray block treatment when manufacturing) or the top side or top and bottom both sides should be treated with photocatalytic coating (nano-coating) from mineral binding.

-

-

Submission Materials

Shop Drawing needed for construction and process plan must be approved from the supervisor and field director before proceeding

with construction. Proceed with work ensuring there is no disruption to the process.

Product test report Must submit a copy of test report of the basic physical property domestically and internationally. If the customer asks a special request, must submit according to what is discussed with the customer.

-

-

Environmental conditions

When installing PLAGLAS®, the temperature must be over 4°C. Do not install when the relative humidity is high than 90% or when it is raining. Sealing material filling should not be done when the relative humidity is more than 90%.

-

-

Construction range

Construction scope of PLAGLAS is limited to the roof including light receiving board, window frames, and wall finishing work.

Other work will be done according to the details of construction subcontract.

-

-

Change of design

Any changes in design due to field conditions in the construction process must be done after discussion between “A” and “B”.

Any changes in the construction cost are calculated after work.

PLAGLAS® Length & Assembly

PLAGLAS®s an extrusion molded product; it can be manufactured in any length but it can be limited according to moving means or field conditions.

6m in length is the most appropriate, considering workability and constructability; when working on a curved structure

it must be designed and built considering the maximum allowed radius of curvature. (Maximum allowed curvature radius(mm): Thickness(T)×180).

Construction procedure

-

01

-

Unloading

Unload the materials by using the easiest one of the below 2 methods, according to the field conditions. Unload by using fork lift Unload by using hoisting equipment

-

02

-

Field receiving inspection

For receiving inspection, material size, appearance (packaging, surface stains, damage, foreign substance, cutting etc.) must be inspected. Failed products in the receiving inspection should be treated according to the contract provisions and mutual agreement. In case nonconforming products occur before or after moving or construction, separate and store nonconforming products and return the

products to the factory appropriately to the field conditions, under mutual agreement between “A” and “B”.

-

03

-

Loading and transporting

The material brought into the field should be stored near the site where loading work is to be done, by principle. Support a transporting palette (1mX 2.4m) within 1m under the transported material to prevent damage of the material and make it easy to

use a fork-lift when unloading. Maintain within 3m distance between people when it is moved by people, to prevent material from bending or changing form. Transport using means constructed as needed in the field. (e.g. roller or rails etc. installed in the field).

-

04

-

Handling and storage

Loading Place the materials horizontally on a level area ensuring the PLAGLAS® is not damaged, after putting within every 1m ground supports

such as palettes or wood. If the sizes vary load the largest or longest material first. If the material must be loaded vertically, they should be close together by 10° on

a wooden support, and the same material board thickness must be less than 30cm. Handling and storage The loaded PLAGLAS® at the site but be protected sufficiently to prevent any damage from external impact. PLAGLAS® should not be exposed to direct sunlight, stored in a ventilated area out of sunlight, and stored not exposed to a temperature

higher than 40℃.

When the protective film is intact, it should be stored away from heat or direct sunlight. Protection The PLASGLAS® must be brought in with the protective films intact on both sides, they should be removed after construction is finished.

-

05

-

Cleaning and Care

Take care not to be contaminated with paint or cement water after installing PLAGLAS®. • A mix of warm water(25℃~35℃) and a neutral detergent and a cotton towel should be used to clean dust or dirt on the surface of PLAGLAS®.

-

06

-

Cautions when installing

Designated electric cutter should be used to cut; be accurate in finishing of the cutting. Cutting speed of the device should be quick but slow in moving speed. For the screws or bolts needed for other construction, rust prevented ones or stainless screws should be used. Using acetic acid or non-acetic acid oxime silicone can make cracks in the products.

-

07

-

Approval for completion of the construction

Approval should be received from the construction manager after removing all debris from cutting, protective films and silicone buckets,

after construction is completed. After receiving approval from the field supervisor and completion of all process and clean-up, receive construction completion

confirmation document.

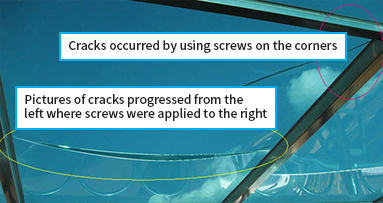

Causes for cracks

Occurrence and causes of defects in construction

| Cause | Phenomenon |

|---|---|

| When a screw is directly put on a board | Fine cracks occurring where screws are used initially from contraction and expansion ⇒ contraction and expansion continue ⇒ Cracks occur (Mostly towards width direction) |

| The crack is more severe when the board’s length is long, which makes the contraction and expansion is larger | |

|

When silicone is used where polycarbonate should be used; Or when silicone for polycarbonate is used in a blocked or enclosed area |

Crack occurs due to chemical reaction or crumbs occur from corrosion |

|

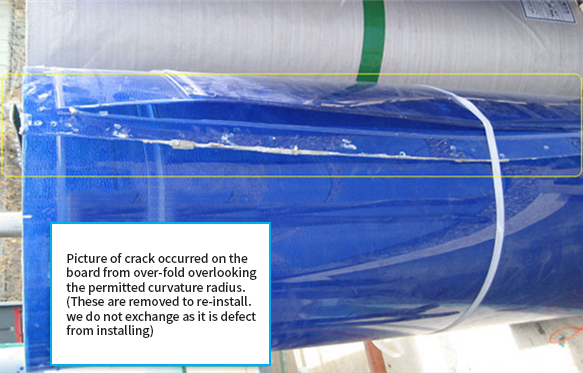

When the curvature radius went over the permitted range |

Cracks occur due to continuous stress, contraction and expansion is put on the curved surface; or cracks in sharp open cuts occur |

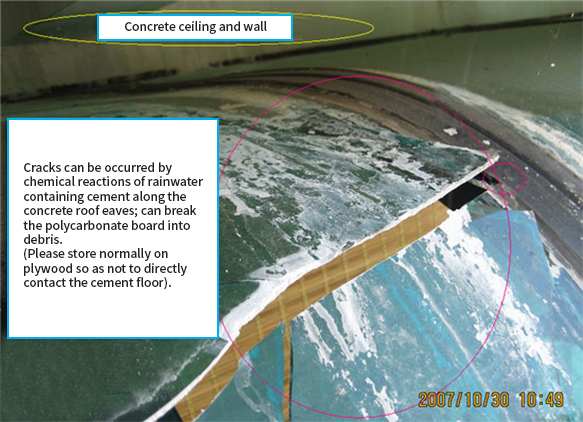

Crack or corrosion can occur when there are factors that can cause chemical reaction in the near environment when storing the polycarbonate products.

Cracks can occur when the products are stored & rolled up in smaller curve radius than permitted if it is put on impact or stored for a prolonged time.

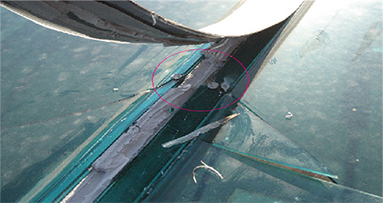

Crack occurred by using screws

Crack occurred by using screws

Cracks occurred when installing screws – (Initially)

Cracks occurred from applying screw

– (Toward end)

-

01

-

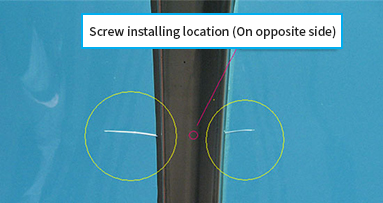

Please, make a hole on the polycarbonate board, little larger than the diameter of the screw before screwing. Contraction and expansion (0.07mm difference occur per 1m /1℃.) ccur due to change in the temperature.

If holes are not made before applying, the polycarbonate cannot contract and expand naturally, so fine cracks occur from the screw part

to make cut to the opposite side.

-

02

-

Please do not apply the screws too tight when screwing. When the screws are applied too tight, the screw heads leave fine crack on the PC board and press the PC board to cause cracks as contraction

and expansion repeat to the change in the temperature. (Only tighten the screws at the part where the screw thread and groove end)

-

03

-

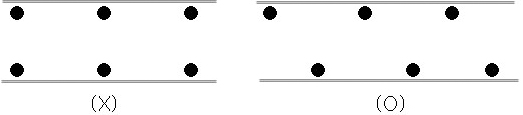

Apply minimum numbers of screws if screwing is required; do not apply them in a straight line but apply in zigzags on both sides.

-

04

-

Screws should not be applied in principle. We do not replace or compensate products in the case of cracks occurred by screwing.

Please notify and inform the customers about it before using.

Importance of permitted curve radius

-

01

-

Installing on curves Please apply curvature radius according to the thickness of the product when designing and constructing on a flat or curved surface.

Bending and installing on curved area can be easily worked on polycarbonate in room temperature.

The permitted value of the curvature radius must be specially noted when working on these.

Cracks may occur if this is overlooked and curving work is done putting overloaded pressure.

We do not exchange or compensate the defects occurred from these problems; please educate and notify the customers.

-

02

-

Maximum permitted curvature radius (Radius) A. Single layer: 200 times the layer thickness B. Multiple layers 10T: More than 1,500mm, - 16T : More than 2,500mm

Importance of permitted curvature radius

Cracks and defect by chemical reaction

-

01

-

Polycarbonate products are chemicals. When these are stored on PVC floors or concrete grounds, or in a place where toxic chemical products or oil can flow in, harmful chemical

ingredients can be infiltrated to cause rupture on the contaminated surface from chemical reaction, to cause cracks to occur.

(We recommend using plywood for the flooring) Please, first-in & first-out to avoid storing products for too long.

Cracks and damage by chemical reaction

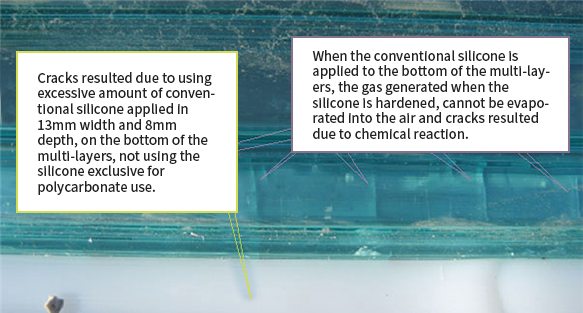

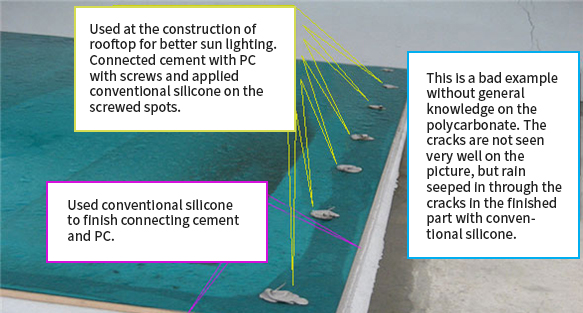

Proper use of Silicone on PC

When using general silicone, applying excessive silicone, or

when there is no outlet for gas to release when the silicone is hardened, the silicone and polycarbonate board reacts chemically.

This can lead to cracks from occurring. Acetic acid-free, alcohol hardened type silicone should be used; when oxime type

of the acetic or acetic acid-free type is used it can make cracks on the board from chemical reaction.

Especially, silicone should not be flowed or filled into the multi-layer sheet, Archilight (Cracks are occurred from gas emit).

| Silicones permitted to use | Oxime type silicone not recommended to use | |

|---|---|---|

| Dongyang Chemicals | KSCS 2100 |

Dow Corning DC Double N DC 789 Koryo Chemicals SL 868 Other general silicone etc. |

| SILPRUP | ||

| GESIL-N | ||

| XE 0814 | ||

| Dow Corning | PLASEAL | |

| DC 795 | ||

| DC 791-N | ||

| Koryo Chemicals | SL 968 | |

| Wacker Chemicals Korea Co., Ltd. (manufactured from) |

LC798 (Sold from: PNB Woochang Co., Ltd.) | |

Many users start using the silicone exclusive for polycarbonate through a lot of promotions & educations on it,

but other customers or individuals still do finishing work using conventional silicon on the PC board purchased.

Problems are being occurred as time passes after conventional silicon treatment, making cracks or crumble due to chemical reactions.

When these failures happen, there is great human labor, time and cost lost in order to remove, re-purchase materials and re-install.

The silicone exclusively for polycarbonate is a little more expensive, but compared to the cost of re-installment,

using special silicone would be stable and cost-effective.

No replacement or refund will be made in the case of the cracks or breakages caused by using conventional silicone.

Please, make sure to notice your customers about using the right silicone for PC to the customers.

Example of silicone misused.

Example of silicone misused.

Proper handling and installation

Handling

Take a caution on safety when loading/unloading and transporting of the products as they are heavy weight.

It gives the products huge impact if you push them with feet from the truck to let them fall on the ground.

Especially, if you put impact to the edges of the rolled up products when transporting, it can damage the products.

Storage and Cautions

When loading vertically, they must be stacked closely in 10˚ degrees, the thickness of the same loading board should be less than 30cm.

When loading horizontally, load on palettes of even height, of the same sized products. If the products are not same sizes, put larger sizes first on the bottom.

Store in level grounds where there are no contaminants or water dropping. Must be stored in a well ventilated indoors, avoiding an area directly exposed

to direct sunlight, where rain may leak, or where it is high-temperature and high-humidity over 40℃.When stored indoors, cracks may occur if they are placed

in PVC flooring or on concrete floor wet from recent construction. Store so that the convex surface or pointed surface do not directly contact each other.

-

○

-

○

-

X

-

X

-

○

-

X

Cautions on the protective films

-

01

-

The protective films on the goods may not be removed if they are stored a long time where direct sunlight is in contact.

-

02

-

The film does not get removed well if exposed in high heat over 60℃.

-

03

-

Remove the protective films (paper, plastic) immediately after installment is completed.

-

04

-

When the protective films are not easy to remove, place them in agents (isopropyl alcohol,

naphtha, or 2-butoxybutyl cellosolve ethanol) for 15 – 30 minutes then remove them.

Cutting and drilling

-

01

-

They can be cut by saws protect the eyes when working.

-

02

-

Use the cutting saws when the rotation numbers qualify the provisions

when the cutting surface is not smooth, smooth them out with rasps or sand paper.

-

03

-

The cutting speed of the tools should be fast, moving speed should be slow when cutting.

-

04

-

The size of the holes should be slightly larger than the bolts considering the expansion.

-

05

-

Avoid using bolts to fix the products as they may cause cracks to occur.

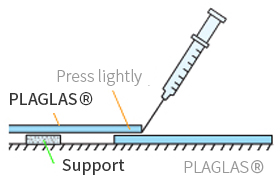

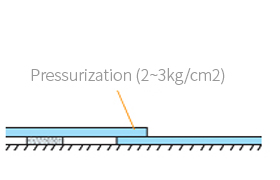

Adhesion method (Solvent adhesion)

Solvent adhesion is adhering the polycarbonates together.

The simplest and effective method is to use ethylene chloride solution.

-

01

-

Adhesion method Preliminary treatment If the surface is contaminated with oil etc. clean with methanol or neutralizer. Adhesion When the ethylene chloride solution is applied on the surface with a syringe, the surface swells and dissolves, so must be adhered quickly.

When high adhesion strength and heat resistance is desired, if you give a little time after applying ethylene chloride solution before adhering,

it results in better adhesion results. Let it stand for more than 5 hours in room temperature before use, after adhesion is done.

How to Clean

-

01

-

Clean dust or dirt with water, then apply water soluble mild detergent, cleaning agents like naphtha,

and ethanol on a soft cloth or sponge and clean. Then rinse with warm water and remove moisture.

-

02

-

Please take caution when material causing abrasion, benzene, gasoline, toluene, acetone, and alkaline detergents are used,

as they can generate surface damage, chalking or cracks.

Cautions when using silicone

-

01

-

Alcohol type silicone from the acetic acid-free types should be used. Acetic acid or non-acetic acid,

oxime type silicone is prohibited from use, as cracks may occur on the sheet surfaces due to chemical reactions.

-

02

-

Especially, silicone should not be flowed or filled into the holes of multi-layer sheet, Archilight.

| Oxime type silicones prohibited from use | Usable silicone | |

|---|---|---|

| DC Double N, DC 789, SL 868 etc. | Dongyang Chemicals | SILPRUP, GESIL-N, XE0814 |

| Dow Corning | PLASEAL, DC 795, DC 791-N | |

| Koryo Chemicals | SL 988 | |

| TOSHIBA | TOS SEAL 38 | |

| TORAY | SE 555 | |

Gaskets permitted to use

E.P.D.M. or Neoprene base is appropriate to use. Do not use PVC Gasket.